Quality Assurance and Traceability

This is an essential feature of SN Interplume process.

Strict products' specifications, compliance with the most stringent international standards and regulations, form the basis of our commitment to quality.

Our internal laboratory, equipped with all necessary tools and machinery, ensures a permanent monitoring of our production.

The Quality Control team's expertise and accuracy are verified by EDFA - European Down & Feather Association - and by the IDFB - International Down & Feather Bureau - through annual tests assessing their performance and relevance of results. The QC team is also in charge of our products' traceability and R & D projects.

Quality Control

Controls begin on receipt of the raw material, and this continues throughout the production process, through systematic checks to avoid any possibility of non-compliance.

The products are subject to the following tests:

- Olfactory test

- Composition (determination of feather and down content)

- Turbidity

- Oil & Fat

- Oxygen Index

- Filling Power

Only fully validated lots are stored and shipped. In case of non-conformity, even on a single criterion, the batch is returned to the relevant manufacturing stage for reprocessing.

Traceability

Traceability is the capability to find, through all stages of production, the history and/or use of a product by means of recorded documentation.

Full traceability takes into account each stage in production, as well as over the entire supply chain.

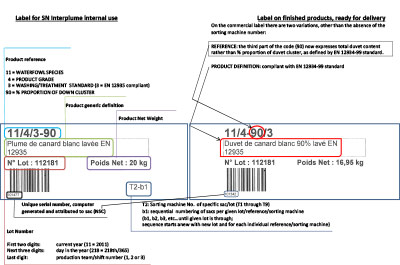

Our Full Traceability System is centred on a batch number defined by day and by production team, as well as by product type. The necessary information is coded on the label:

Our system is approved and certified by EDFA, in accordance with the results of independent and regular audits of our supply chain by the International Down & Feather Laboratory (IDFL).

The finished products shipped to customers are therefore identified, enabling us to reconstruct their background.